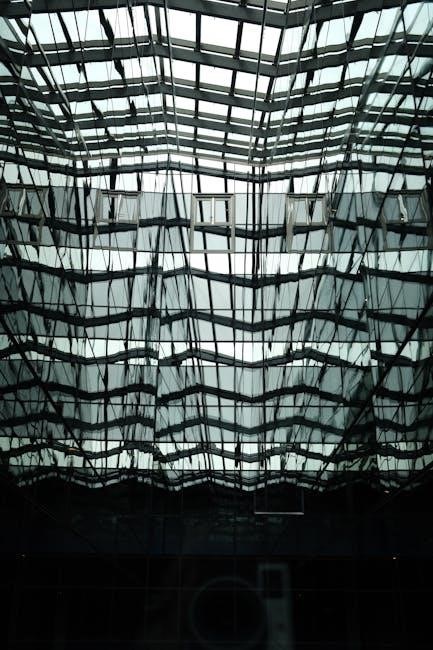

Standing seam metal roofing features flat pans and raised vertical seams‚ offering weather-tight performance and a sleek‚ modern aesthetic for residential and commercial buildings․

1․1 What is Standing Seam Metal Roofing?

Standing seam metal roofing is a weather-tight system featuring flat pans and raised‚ interlocking vertical seams․ It is a concealed fastener design‚ with panels attached via clips or fasteners hidden beneath the seams․ The vertical legs of the panels snap or mechanically lock together‚ ensuring a secure and watertight seal․ Available in various materials like steel‚ aluminum‚ zinc‚ and copper‚ standing seam roofs are known for their durability‚ fire resistance‚ and energy efficiency․ They are suitable for slopes as low as 3:12‚ making them versatile for residential and commercial applications․ This system is celebrated for its sleek‚ modern appearance and long-lasting performance․

1․2 History and Evolution of Standing Seam Roofs

Standing seam metal roofing has its roots in ancient civilizations‚ where metal was first used for waterproofing․ The concept of interlocking seams emerged in the mid-19th century with corrugated iron roofs․ Over time‚ advancements in materials and manufacturing led to the development of modern standing seam systems․ Initially used for commercial and agricultural buildings‚ they gained popularity in residential architecture in the late 20th century․ Today‚ standing seam roofs are a preferred choice for their durability‚ aesthetic appeal‚ and energy efficiency‚ with continuous innovations in design‚ materials‚ and installation techniques further enhancing their performance and versatility․

Benefits of Standing Seam Metal Roofs

Standing seam metal roofs offer exceptional durability‚ weather resistance‚ and a sleek‚ modern appearance‚ making them a versatile and long-lasting choice for various architectural designs․

2․1 Aesthetic Appeal and Design Flexibility

Standing seam metal roofs offer a sleek‚ modern appearance with clean lines and smooth surfaces‚ complementing various architectural styles․ The panels can be bent to create hems and are available in multiple widths and finishes‚ providing design flexibility․ Homeowners can choose from a wide range of colors and finishes‚ allowing for tailored aesthetic solutions․ The vertical leg of the panels creates a subtle shadow effect‚ enhancing the roof’s visual appeal․ This versatility makes standing seam metal roofs suitable for both contemporary and traditional designs‚ ensuring a harmonious blend with any building’s exterior․ Their aesthetic appeal is further boosted by the ability to customize details like ridge caps and flashing․

2․2 Durability and Longevity

Standing seam metal roofs are renowned for their exceptional durability and longevity‚ often lasting 30 to 50 years or more․ Constructed from high-quality materials like zinc‚ aluminum‚ and stainless steel‚ these roofs withstand harsh weather conditions‚ including heavy rain‚ hail‚ and extreme temperatures․ Their weather-tight design prevents water infiltration‚ reducing the risk of leaks and structural damage․ Additionally‚ standing seam roofs are fire-resistant and impact-resistant‚ making them a resilient choice for various climates․ With proper installation‚ they require minimal maintenance and remain structurally sound for decades‚ outperforming traditional roofing materials like asphalt shingles․ Their durability ensures long-term protection and value for homeowners and businesses alike․

2․3 Weather Resistance and Water Tightness

Standing seam metal roofs excel in weather resistance and water tightness due to their interlocking design․ The raised seams tightly interlock‚ creating a barrier against water infiltration․ This system is particularly effective in preventing leaks‚ even in areas with heavy rainfall or snow․ The panels’ smooth surface allows snow and ice to slide off easily‚ reducing the risk of damage from winter conditions․ Additionally‚ the concealed fasteners eliminate exposed gaps‚ further enhancing water resistance․ These features make standing seam roofs ideal for regions with harsh climates‚ ensuring long-lasting protection and minimizing maintenance needs․ Their superior water-tight performance is a key advantage over other roofing materials․

Design and Profiles of Standing Seam Roofs

Standing seam roofs offer versatile design options‚ including snap-lock and mechanical lock profiles‚ with vertical legs and shadow effects‚ enhancing both functionality and aesthetic appeal․

3․1 Snap-Lock Standing Seam Profiles

Snap-lock profiles are a popular choice for standing seam roofs‚ featuring roll-formed male and female legs that interlock without requiring mechanical seaming․ This design simplifies installation‚ as panels can be easily snapped into place‚ reducing labor costs․ The snap-lock system provides excellent water resistance and a sleek appearance‚ making it suitable for various architectural styles․ Panels are typically 14 to 18 inches wide‚ with a flat pan and raised seams for structural integrity․ This profile is ideal for both residential and commercial projects‚ offering durability and a modern aesthetic while minimizing maintenance needs over time․

3․2 Mechanical Lock Standing Seam Profiles

Mechanical lock standing seam profiles are designed for durability and weather-tightness‚ utilizing a system where panels are mechanically seamed together․ This method ensures a secure connection‚ especially on roofs with lower slopes‚ by using a hand or mechanical seamer to crimp the seams․ The panels typically range from 14 to 18 inches in width‚ with raised vertical legs that provide structural strength․ This profile is highly resistant to wind uplift and water infiltration‚ making it ideal for harsh weather conditions․ Mechanical lock systems are commonly used in both residential and commercial applications‚ offering a balance of strength‚ versatility‚ and aesthetic appeal․

3․3 Vertical Leg and Shadow Effects

The vertical leg in standing seam metal roofing enhances structural integrity and creates a distinct shadow effect․ This design element adds visual depth‚ making the flat panels appear sleek and modern․ The vertical leg’s height varies‚ influencing the roof’s aesthetic impact․ Taller legs emphasize the shadow‚ offering a more dramatic appearance‚ while shorter legs provide a subtler look․ This feature complements various architectural styles‚ from contemporary to traditional designs․ The shadow effect is particularly pronounced in sunlight‚ adding dynamic visual interest to the building’s exterior․ This design flexibility makes standing seam roofs a popular choice for both residential and commercial projects‚ blending functionality with style․

Installation Process of Standing Seam Metal Roofs

Installation involves measuring‚ cutting panels‚ and attaching them with clips and fasteners․ Eave‚ ridge‚ and valley details are critical for ensuring a watertight and secure finish․

4․1 Panel Length and Cutting Requirements

Standing seam metal roof panels typically range from 4 to 45 feet in length‚ depending on the project’s specifications․ Panels are pre-cut to fit specific roof dimensions‚ ensuring minimal waste and seamless installation․ Cutting is usually done with specialized tools‚ such as shears or saws‚ to maintain precision and avoid damage to the material․ Proper measurement is critical to ensure panels align correctly with the roof’s slope and structure․ Cutting requirements may vary based on the roof’s complexity‚ including valleys‚ hips‚ and eaves․ Accurate cuts are essential for achieving a watertight and structurally sound installation․ Safety precautions‚ like wearing protective gear‚ are also important during cutting․

4․2 Fastening Systems and Clips

Standing seam metal roofs utilize concealed fastening systems‚ ensuring a sleek appearance and enhanced durability․ Clips are attached to the roof deck and engage with the vertical legs of the panels‚ allowing for thermal expansion and contraction․ These clips are typically made from durable materials like stainless steel or high-strength plastics to withstand harsh weather conditions․ Fasteners are designed to provide a secure hold without penetrating the panels‚ minimizing the risk of leaks․ The spacing and type of fasteners depend on the roof’s pitch‚ load requirements‚ and local building codes․ Proper installation of fastening systems is crucial for maintaining the roof’s structural integrity and weather-tightness over time․

4․3 Eave‚ Ridge‚ and Valley Details

Eave‚ ridge‚ and valley details are critical for ensuring the structural integrity and water-tightness of standing seam metal roofs․ The eave trim is typically secured with fasteners or clips‚ providing a smooth transition from the roof to the fascia․ Ridge caps are installed along the roof’s peak‚ often with weatherproof seals to prevent moisture infiltration․ Valleys‚ where two roof slopes meet‚ require pre-formed or field-fabricated panels to ensure a seamless fit and proper water flow․ Flashings and sealants are used at these intersections to reinforce protection against leaks․ Proper detailing in these areas is essential for maintaining the roof’s functionality and aesthetic appeal․

Cost of Standing Seam Metal Roofs

Standing seam metal roofs cost $10 to $18 per square foot installed‚ depending on materials‚ size‚ and labor․ Average total costs range from $14‚000 to $19‚000․

5․1 Average Cost Per Square Foot

The average cost of standing seam metal roofing ranges from $10 to $18 per square foot‚ including installation․ This cost varies based on the type of metal‚ roof size‚ and labor rates․ For a standard 3‚000-square-foot roof‚ the total cost can range from $14‚000 to $19‚000․ Factors such as roof pitch‚ material thickness‚ and fastening systems also influence the price․ While the upfront cost is higher than traditional roofing materials‚ standing seam metal roofs offer long-term savings through durability and energy efficiency․ This makes them a valuable investment for homeowners and businesses seeking a reliable‚ low-maintenance roofing solution․

5․2 Factors Influencing the Cost

The cost of standing seam metal roofing is influenced by several factors‚ including roof size‚ pitch‚ and complexity․ Material choice‚ such as aluminum or zinc‚ also affects pricing‚ as does the thickness of the panels․ Labor costs vary by location and installer expertise․ Additionally‚ the need for custom detailing‚ such as eave and ridge components‚ can increase expenses․ Panel length and cutting requirements further impact the total cost‚ as longer panels may reduce waste but require precise measurements․ Regional demand and supplier pricing also play a role․ These factors combined make it essential to consult local contractors for accurate quotes tailored to specific projects․

5․3 Long-Term Cost Efficiency

Standing seam metal roofs offer significant long-term cost efficiency due to their durability and low maintenance requirements․ With a lifespan of 30 to 50 years or more‚ they reduce the need for frequent replacements․ Their weather-resistant design minimizes repair costs from leaks or damage․ Energy efficiency is another benefit‚ as reflective surfaces can lower cooling expenses․ Additionally‚ metal roofs retain their value‚ often increasing a property’s resale value․ While the initial investment is higher‚ the long-term savings from reduced maintenance‚ energy efficiency‚ and extended lifespan make standing seam metal roofs a cost-effective choice for both residential and commercial applications․

Maintenance and Repair of Standing Seam Roofs

Standing seam metal roofs require minimal upkeep‚ with periodic cleaning and inspections to ensure longevity․ Addressing minor issues promptly prevents costly repairs and maintains their durability․

6․1 Low Maintenance Requirements

Standing seam metal roofs are renowned for their minimal maintenance needs due to their durable design and concealed fasteners․ Unlike traditional roofing materials‚ they don’t require frequent repairs or replacements․ The smooth surface naturally sheds debris‚ reducing the risk of clogged gutters and water damage․ Regular inspections are recommended to ensure clips and fasteners remain secure․ Cleaning the roof occasionally to remove dirt and stains helps maintain its aesthetic appeal․ Additionally‚ the absence of exposed fasteners reduces the likelihood of leaks‚ making these roofs a practical choice for homeowners seeking long-term reliability with less upkeep․ This low-maintenance feature enhances their overall value․

6․2 Common Issues and Solutions

Despite their durability‚ standing seam metal roofs can experience issues like scratches during installation‚ which can be addressed by using painter’s tape and touch-up paint․ Oil canning‚ visible as waviness‚ can occur due to improper panel installation or extreme temperatures‚ but this is often more aesthetic than structural․ Fastener issues‚ such as loosening‚ can be resolved by using high-quality‚ compatible fasteners and regular inspections․ Leaks at seams may arise from poor installation or damage‚ requiring re-sealing or replacing affected panels․ Addressing these issues promptly ensures the roof’s longevity and performance․ Proper maintenance and repairs can mitigate potential problems effectively․

6․3 Inspection and Cleaning Tips

Regular inspections are crucial for maintaining the integrity of standing seam metal roofs․ Start by examining the roof from the ground to identify loose fasteners‚ dented panels‚ or signs of wear․ During cleaning‚ use mild detergents and soft-bristle brushes to avoid scratching the surface․ Avoid using abrasive materials or harsh chemicals‚ as they can damage the finish․ Remove debris like leaves and branches promptly to prevent moisture buildup․ Inspect seams and fasteners for gaps or rust‚ addressing them immediately․ Schedule professional inspections annually‚ especially after severe weather events‚ to ensure the roof remains watertight and secure․ Regular maintenance extends its lifespan and appearance․

Comparison with Other Roofing Materials

Standing seam metal roofs outperform traditional materials like asphalt shingles and corrugated metal‚ offering superior durability‚ weather resistance‚ and aesthetic appeal for modern architectures․

7․1 Standing Seam vs․ corrugated Metal Roofs

7․1 Standing Seam vs․ Corrugated Metal Roofs

Standing seam metal roofs differ from corrugated metal roofs in design and functionality․ Standing seam roofs feature flat pans and raised vertical seams‚ offering a sleek‚ modern appearance‚ while corrugated roofs have a wavy‚ ribbed pattern that provides structural strength․ Standing seam systems are more weather-tight due to their concealed fasteners‚ reducing the risk of leaks․ They also offer better durability and are less prone to damage from heavy weather conditions․ In contrast‚ corrugated roofs are more cost-effective and easier to install‚ making them a popular choice for agricultural and industrial buildings․ However‚ standing seam roofs provide a more refined look suitable for residential and architectural applications․

7․2 Standing Seam vs․ Asphalt Shingles

Standing seam metal roofs and asphalt shingles differ significantly in durability‚ aesthetics‚ and maintenance․ Standing seam roofs are highly durable‚ lasting 30-50 years or more‚ while asphalt shingles typically last 20-30 years․ Metal roofs offer superior weather resistance‚ fire resistance‚ and energy efficiency‚ making them a long-term investment․ Asphalt shingles are more affordable upfront but require more frequent replacements․ Standing seam roofs provide a sleek‚ modern appearance‚ while shingles offer a traditional look․ Metal roofs are also low maintenance and resistant to pests and mold․ However‚ they can be noisier during rain and more expensive to install․ Both options suit different budgets and preferences․

7․3 Standing Seam vs․ Slate and Tile Roofs

Standing seam metal roofs are lightweight compared to slate and tile roofs‚ making them ideal for structures with weight constraints․ Slate and tile roofs are durable but heavy‚ requiring reinforced support․ Metal roofs offer comparable longevity‚ lasting 30-50 years‚ while slate can last 50-100 years․ However‚ metal roofs are more cost-effective upfront and require less maintenance․ Slate and tile provide a traditional‚ luxurious appearance‚ whereas metal roofs offer a modern‚ sleek look․ Both options are fire-resistant‚ but metal roofs excel in weather resistance and energy efficiency․ Slate and tile are better for historic designs‚ while metal suits contemporary styles․ Each choice balances aesthetics and practicality․

Technical Specifications and Requirements

Standing seam panels are typically 14–18 inches wide‚ with a minimum 3:12 slope․ Stainless steel fasteners are recommended for durability and weather resistance․

8․1 Minimum Slope Requirements

Standing seam metal roofs require a minimum slope of 3:12 to ensure proper water runoff and prevent ponding․ This slope ensures the system’s weather-tight integrity and structural stability․

8;2 Panel Dimensions and Thickness

Standing seam metal roof panels are typically preformed or field-formed with finished widths ranging from 14 to 18 inches․ The panels can vary in length‚ with a minimum of 4 feet and a maximum of 45 feet‚ depending on the project requirements․ Thickness options vary from 0․40 gauge to 0․70 gauge‚ ensuring durability and structural integrity․ Thicker panels are often used for larger spans or heavier loads․ The dimensions and thickness are chosen based on the building’s design‚ load-bearing needs‚ and local building codes to ensure optimal performance and longevity․ Proper sizing is critical for achieving a weather-tight and visually appealing installation․

Fasteners and clips are critical components in standing seam metal roofing systems․ Clips are typically engaged with the vertical legs of the panels‚ securing them to the roof deck without exposing fasteners․ Stainless steel fasteners are recommended to ensure durability and resistance to corrosion․ Clips are designed to allow for thermal expansion and contraction‚ preventing damage from temperature fluctuations․ Specifications may vary based on the system and manufacturer‚ but they must comply with industry standards to ensure structural integrity and weather-tightness․ Proper installation of fasteners and clips is essential for maintaining the roof’s performance and longevity‚ especially in harsh weather conditions․ Standing seam metal roofs are popular for both residential and commercial projects‚ offering durability and aesthetic appeal․ They are ideal for historical restoration and modern architectural designs․ Standing seam metal roofs are increasingly popular for residential applications due to their durability‚ aesthetic appeal‚ and energy efficiency․ Homeowners appreciate the sleek‚ modern look of flat pans and raised seams‚ which complement various architectural styles․ These systems are ideal for both new constructions and renovations‚ offering a weather-tight solution with minimal maintenance․ Panels are typically 14 to 18 inches wide and can be bent to create custom hem details for eaves and ridges․ The concealed fastener design ensures no exposed screws‚ enhancing both functionality and visual appeal․ Residential projects often highlight the material’s ability to withstand harsh weather conditions while maintaining a timeless‚ sophisticated appearance․ Standing seam metal roofs are widely used in commercial settings for their durability‚ weather resistance‚ and low maintenance requirements․ These systems are ideal for large-scale applications‚ offering a sleek‚ modern aesthetic that enhances building facades․ Commercial projects often utilize panels with widths ranging from 14 to 18 inches‚ featuring concealed fasteners for a clean appearance․ The vertical legs and interlocking seams provide excellent water tightness‚ making them suitable for flat or low-sloped roofs․ Additionally‚ the material’s fire resistance and impact resistance ratings ensure compliance with building codes․ Many commercial standing seam roofs are designed to support sustainable practices‚ such as solar panel integration‚ aligning with modern environmental standards․ Standing seam metal roofing has been a cornerstone in historical and architectural designs‚ offering timeless durability and aesthetic appeal․ Historically‚ these roofs were used in 19th-century buildings‚ showcasing their weather-resistant and fire-retardant properties․ Architecturally‚ standing seam roofs are prized for their versatility‚ blending seamlessly into both modern and traditional designs․ Their clean lines and raised seams create a distinctive visual impact‚ making them ideal for landmarks and heritage restorations․ Many historical structures have been preserved using standing seam systems‚ maintaining original aesthetics while enhancing performance․ The material’s ability to mimic traditional roofing styles‚ coupled with its resilience‚ makes it a preferred choice for architects and historians alike․ Standing seam metal roofing offers exceptional durability‚ aesthetic appeal‚ and weather resistance‚ making it a top choice for modern and historical buildings․ Advances in materials and designs are expected to further enhance its sustainability and energy efficiency‚ ensuring its continued popularity in the roofing industry․ Standing seam metal roofing is a premium roofing system characterized by its flat pans and raised vertical seams‚ offering exceptional weather-tightness and durability․ Its concealed fastener design ensures minimal maintenance and a sleek appearance‚ suitable for both modern and historic architectural styles․ The system is highly resistant to weather elements‚ fire‚ and impact‚ making it a reliable choice for long-term performance․ With various profiles and designs available‚ standing seam roofs provide design flexibility while enhancing the structural integrity and energy efficiency of buildings․ Their popularity continues to grow due to their proven durability and aesthetic appeal․ The metal roofing industry is evolving with advancements in materials‚ sustainability‚ and energy efficiency․ Standing seam systems now incorporate innovative coatings that enhance durability and reflectivity‚ reducing energy consumption․ Manufacturers are adopting eco-friendly practices‚ such as recycling metal scraps and using solar-friendly finishes․ Additionally‚ there is a growing focus on integrating renewable energy systems‚ like solar panels‚ into standing seam roofs for seamless energy harvesting․ Technological improvements in roll-forming machines enable precise panel fabrication‚ reducing waste and improving installation efficiency․ These trends highlight the industry’s commitment to sustainable‚ high-performance roofing solutions that meet modern architectural and environmental demands․8․3 Fastener and Clip Specifications

Case Studies and Real-World Applications

9․1 Residential Standing Seam Roof Projects

9․2 Commercial Standing Seam Roof Projects

9․3 Historical and Architectural Applications

10․1 Summary of Standing Seam Metal Roofing

10․2 Emerging Trends in Metal Roofing Technology

Leave a Reply

You must be logged in to post a comment.