Manual key cutting tools are essential for locksmithing, enabling precise key duplication and repair. These tools, including machines and hand files, ensure accurate key shaping and fitting.

Definition and Purpose

Manual key cutting tools are devices used to duplicate or repair keys by shaping and cutting key blanks to match existing keys. These tools, such as key cutting machines, hand files, and duplication kits, are essential for locksmiths to create precise key copies. Their primary purpose is to ensure that keys fit perfectly into locks, restoring or maintaining proper functionality. Manual tools are valued for their precision, versatility, and ability to handle various key types, making them indispensable in locksmithing for both emergency and routine key-cutting tasks.

Importance in Locksmithing

Manual key cutting tools are indispensable in locksmithing, offering precision and control for creating accurate key replicas. They allow locksmiths to handle various key types, from standard to specialized, ensuring reliable outcomes. These tools are essential for emergency situations, as they enable quick key replication without reliance on electricity. Their versatility and cost-effectiveness make them a cornerstone in locksmithing, providing a practical solution for both professionals and enthusiasts. By mastering manual tools, locksmiths can enhance their skills and deliver high-quality service, maintaining the integrity of locks and ensuring secure access for clients.

Brief History and Evolution

Manual key cutting tools trace their origins to early locksmithing, with locksmiths initially using rudimentary files and hammers. Over time, more refined tools emerged, such as hand-cutting devices, enabling precise key replication. The 19th century saw the introduction of mechanical key cutting machines, while the 20th century brought specialized tools for various key types. Despite automation advancements, manual tools remain essential for their precision and versatility. Their evolution reflects the adaptability of locksmithing, blending traditional techniques with modern innovations to meet changing security demands. This history underscores the enduring relevance of manual tools in the craft.

Types of Manual Key Cutting Tools

Manual key cutting tools include key cutting machines, hand files, and duplication kits. Each type offers unique functionality for precise key replication and customization.

Key Cutting Machines

Key cutting machines are specialized tools designed for precise key duplication. They use mechanical or semi-automatic mechanisms to cut keys accurately. These machines are essential for locksmiths, offering efficiency and consistency. They come in various models, catering to different key types and materials. Modern machines often feature adjustable settings for depth and alignment, ensuring a perfect fit. Regular maintenance is crucial to maintain their performance and longevity. With proper use, key cutting machines streamline the locksmithing process, making them indispensable in the trade. Their reliability ensures high-quality results for both standard and specialized keys.

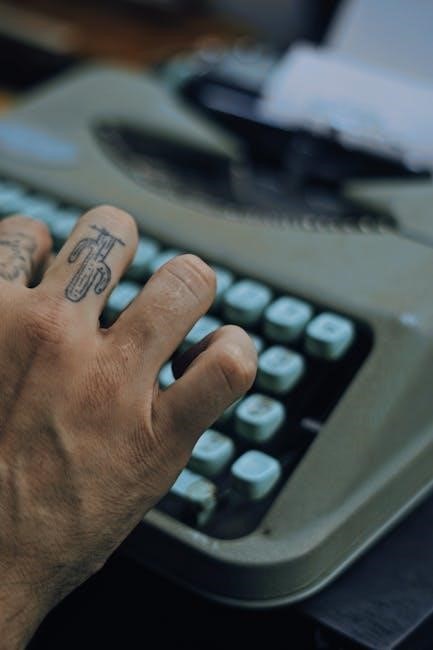

Hand Files and Filing Tools

Hand files and filing tools are fundamental in manual key cutting, offering precision for shaping and refining keys. They are versatile, suitable for various key types and materials. Locksmiths use these tools to manually adjust and smooth key edges, ensuring proper fit and function. Filing tools require skill and patience, as improper use can damage the key. Regular maintenance, such as cleaning and storing tools properly, is essential for longevity. These tools are indispensable for fine-tuning keys, making them a cornerstone in traditional locksmithing practices. Their simplicity and effectiveness ensure they remain a vital part of the trade.

Key Duplication Kits

Key duplication kits are portable, self-contained tools designed for copying keys with precision. They typically include a key gauge, cutting files, and blank keys. These kits are ideal for locksmiths and DIY enthusiasts, offering convenience and versatility. They allow users to duplicate keys without specialized machinery, making them perfect for emergencies or routine tasks. The kits often come with instructions, ensuring even novices can achieve professional results. Their compact design and comprehensive components make them essential for anyone needing to create spare keys quickly and accurately. Key duplication kits are a practical solution for key replication needs.

Specialized Tools for Specific Key Types

Specialized tools are designed for cutting and shaping keys of unique types, such as high-security keys, antique keys, or keys with complex profiles. These tools often include precision cutters, specialized files, and alignment jigs tailored for specific keyway designs. For example, warded keys require picks, while sidebar keys need dedicated cutters to ensure proper alignment. These tools enable locksmiths to handle niche key types with accuracy and efficiency, ensuring the key fits and functions as intended. They are essential for professionals dealing with specialized or high-security locks, where generic tools may not suffice.

How to Use a Manual Key Cutting Tool

Using manual key cutting tools requires aligning the key blank with the original, securing it firmly, and carefully cutting or filing to match the exact shape and size. Always follow safety guidelines to ensure accuracy and avoid errors.

Step-by-Step Guide

Begin by securing the original key and the blank key in the tool’s vice, ensuring proper alignment. Use the cutting wheel to replicate the original key’s teeth, adjusting depth and spacing as needed. File rough edges for smoothness. Test the key in the lock to ensure proper fit and function. If necessary, refine the key further for optimal performance. Always follow safety precautions and maintain tools for longevity. This method ensures precision and reliability in key duplication. Proper technique is crucial for achieving professional results. Patience and attention to detail are key to successful key cutting.

Measuring and Aligning the Key

Start by placing the original key and blank key side by side on a flat surface. Use calipers or a measuring tool to note the precise dimensions and spacing of the original key’s teeth. Secure both keys in the tool’s alignment fixture, ensuring they are perfectly aligned. Adjust the tool’s depth gauge to match the original key’s specifications. Double-check the alignment to avoid mismatches. Proper measurement and alignment are critical for producing an accurate duplicate. Any misalignment can result in a poorly fitting key, requiring additional refinement. Always verify measurements before proceeding to the cutting phase. Precision is key to achieving a functional duplicate.

Cutting and Shaping the Key

Once the key is properly aligned, secure both the original and blank key in the tool’s fixture. Use the cutting wheel or blade to carefully replicate the teeth of the original key onto the blank. Start with light passes, gradually increasing depth as needed. Ensure the tool’s depth gauge matches the original key’s specifications. After cutting, use a file or grinder to smooth out any rough edges or burrs. For intricate keys, specialized shaping tools may be required. Always maintain steady pressure and work slowly to avoid damaging the blank. Safety goggles and gloves are essential during this process. Inspect the key periodically to ensure accuracy.

Testing and Refining the Key

After cutting, insert the key into the lock to test its fit and functionality. If it doesn’t turn smoothly, identify areas where adjustments are needed. Use a key inspection tool or magnifying glass to examine the teeth for accuracy. Refine the key by carefully filing or grinding uneven or misaligned areas. Repeat the testing process until the key operates flawlessly. For precise adjustments, use a micrometer to measure tooth depths. Keep a set of spare blanks on hand for iterative refining. Patience is crucial, as even small discrepancies can affect the key’s performance. Always clean the lock and key after testing to ensure smooth operation.

Safety Precautions and Best Practices

Always wear safety goggles and gloves when cutting keys to protect against metal shavings. Ensure proper ventilation and keep loose clothing tied back. Maintain a clean workspace to prevent accidents and ensure precise cuts. Regularly inspect tools for wear and tear. Store sharp tools securely and out of reach of children. Follow manufacturer guidelines for tool usage and maintenance. Keep a fire extinguisher nearby in case of emergencies; Properly dispose of metal waste and chemical substances. Stay focused and avoid distractions while operating manual key cutting tools.

Safety Guidelines

When using manual key cutting tools, prioritize safety by wearing protective eyewear and gloves to prevent injuries from flying metal particles. Ensure the workspace is well-lit and free from clutter to minimize accidents. Keep loose clothing and long hair tied back to avoid entanglement with machinery. Use tools only for their intended purposes and follow the manufacturer’s instructions. Regularly inspect tools for wear and tear, replacing them when necessary. Maintain a safe distance from children and pets while working. Properly store tools in a dry, secure location to prevent rust and unauthorized access. Always stay alert and focused during the key cutting process to ensure accuracy and safety.

Common Mistakes to Avoid

When using manual key cutting tools, common mistakes include incorrect alignment of the key blank, insufficient clamping pressure, and using dull or worn-out cutting wheels. Neglecting to measure the key accurately can result in improper fitting. Over-cutting or under-cutting the key teeth is another frequent error, leading to a poorly functioning key. Additionally, failing to wear safety gear, such as goggles, can expose users to metal shavings. Using the wrong tool for the specific key type or material can also cause damage to both the key and the tool. Regular tool maintenance can help prevent these avoidable mistakes.

Maintenance and Care of Tools

Proper maintenance ensures the longevity and efficiency of manual key cutting tools. Regularly clean tools with a soft brush or solvent to remove metal shavings and debris. Lubricate moving parts to prevent rust and friction. Store tools in a dry, secure location to avoid damage or misplacement. Sharpen cutting wheels periodically to maintain precision and avoid dulling. Inspect tools for wear and tear, replacing components as needed. Proper handling and storage prevent accidental damage, ensuring tools remain in optimal condition for consistent performance. Regular maintenance not only extends tool life but also enhances accuracy in key cutting tasks.

Troubleshooting Common Issues

Identify the root cause of key cutting errors, such as misalignment or improper tool calibration. Adjust techniques and ensure correct material selection for optimal results.

Key Doesn’t Fit Properly

A key that doesn’t fit properly is often due to misalignment during cutting or incorrect measurement. Check the key blank alignment and ensure the cutting tool is calibrated. Verify the depth and spacing of the cuts, as even slight deviations can cause issues. If the key is too tight or loose, adjust the cutting tool or file the key edges carefully. Test the key incrementally to avoid excessive material removal. Ensure the key blank matches the original key’s specifications. Proper measurement and alignment are critical for a smooth fit and functionality.

Tool Malfunction or Wear

Tool malfunction or wear can hinder key cutting accuracy and efficiency. Dull cutters or misaligned components are common issues, requiring sharpening or replacement. Regular lubrication of moving parts prevents friction-related damage. Ensure proper tool calibration and use appropriate key blanks to avoid excessive strain. Clean tools frequently to remove debris that may affect performance. Applying too much pressure can accelerate wear, so maintain moderate force during cutting. Inspect tools periodically for signs of wear and address them promptly to maintain optimal functionality and extend tool lifespan. Proper maintenance ensures consistent results and prevents costly repairs or replacements.

Material Selection for Key Cutting

Material selection for key cutting is crucial for durability and functionality. Common materials include brass, nickel-plated brass, and stainless steel, each offering varying levels of strength and resistance to corrosion. Brass keys are cost-effective and widely used, while stainless steel keys are ideal for harsh environments. Always ensure the key blank matches the lock’s specifications to guarantee proper fitting and operation. Using high-quality materials reduces wear on both the key and lock, extending their lifespan. Proper material selection also enhances security, as stronger materials resist tampering and breakage. Choose materials based on the intended use and environmental conditions to achieve optimal results.

Manual vs. Automated Key Cutting Tools

Manual tools offer precision and cost-effectiveness for small-scale tasks, while automated tools provide speed and accuracy for high-volume key cutting, each suited for different locksmithing needs.

Advantages of Manual Tools

Manual key cutting tools offer precision and control, ideal for intricate or specialized keys. They are cost-effective, requiring minimal investment, and suitable for small-scale operations. Portability is another advantage, allowing locksmiths to work on-site. Manual tools also reduce dependency on electricity, making them reliable in remote locations. Additionally, they provide a tactile experience, essential for mastering locksmithing skills. Overall, manual tools remain a vital choice for professionals seeking durability and versatility in various locksmithing tasks.

Disadvantages of Manual Tools

Manual key cutting tools require significant skill and time, making them less efficient for high-volume tasks. They can be labor-intensive, leading to fatigue and potential errors. Limited to basic key types, manual tools struggle with complex modern keys. Replication accuracy depends heavily on the user’s expertise, increasing the risk of improper fits. Additionally, manual tools lack the speed and consistency of automated machines, making them less suitable for commercial locksmithing. Despite their benefits, manual tools are best for small, specialized jobs rather than large-scale operations.

When to Use Manual Tools

Manual key cutting tools are ideal for small-scale, precise tasks where automation is unnecessary. They excel in situations requiring intricate craftsmanship, such as repairing or duplicating vintage keys. Manual tools are portable and cost-effective, making them perfect for locksmiths working on-site or with limited resources. Additionally, they are beneficial for creating custom keys or adjusting unique key types that automated machines cannot handle. For beginners or professionals needing control over minute details, manual tools provide unmatched tactile precision. However, they are less efficient for bulk production, making them best suited for specialized or low-volume tasks where accuracy and personal touch are paramount.

Manual key cutting tools remain essential for locksmiths, offering precision and control. Their versatility for specific tasks ensures their timeless relevance in locksmithing.

Manual key cutting tools are indispensable in locksmithing, enabling precise key duplication and repair. They include machines, hand files, and duplication kits, each tailored for specific tasks. Proper measurement, alignment, and cutting techniques ensure accurate results. Safety precautions, such as wearing protective gear and avoiding overcuts, are crucial. Troubleshooting issues like improper fits or tool malfunctions requires patience and skill. While automated tools offer speed, manual tools provide unmatched control for intricate or specialized keys. Regular maintenance extends tool longevity, ensuring optimal performance. Balancing tradition with modern advancements, manual key cutting tools remain vital in locksmithing, offering reliability and craftsmanship.

Future of Manual Key Cutting Tools

Manual key cutting tools will remain essential in locksmithing, even as technology advances. Their versatility and precision for specialized tasks ensure continued relevance. Innovations like hybrid tools, combining manual techniques with digital guidance, may emerge. Sustainable materials and ergonomic designs could enhance usability. As locksmithing evolves, manual tools will adapt, offering a bridge between tradition and modernity. While automated solutions grow, manual tools will still be indispensable for unique or intricate keys. Their future lies in balancing craftsmanship with innovation, ensuring they remain a vital part of the locksmith’s toolkit for years to come.

Leave a Reply

You must be logged in to post a comment.